Industrial Digitalization

Industrial Digitalization.

Data has the ability to streamline and boost almost every process. Manufacturing processes are no exception to that! Making your production more data driven can result in a higher yield an more efficiency of your production facility. In other words, your output can grow without investing in more machines and your costs can decrease by increasing your OEE. The beauty is that all this can be done by just putting to work data which is already present in your installations.

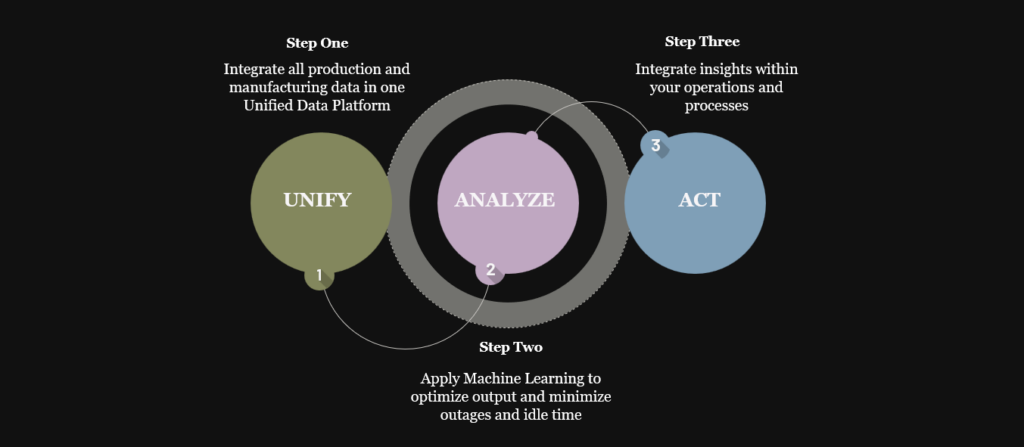

Algorhythm has all the skills and expertise to digitalize and optimize your manufacturing. We propose a 3-step approach to unchain the power which is hidden within your data. First we unify all your relevant IT and OT data. Secondly we apply Machine Learning on this unified data to optimize yield and efficiency. Lastly we operationalize the machine learning models by embedding them within your production processes. In order to do this, we combine a deep knowledge of all things data, with a thorough understanding of manufacturing processes.

· Step 1 – Unify

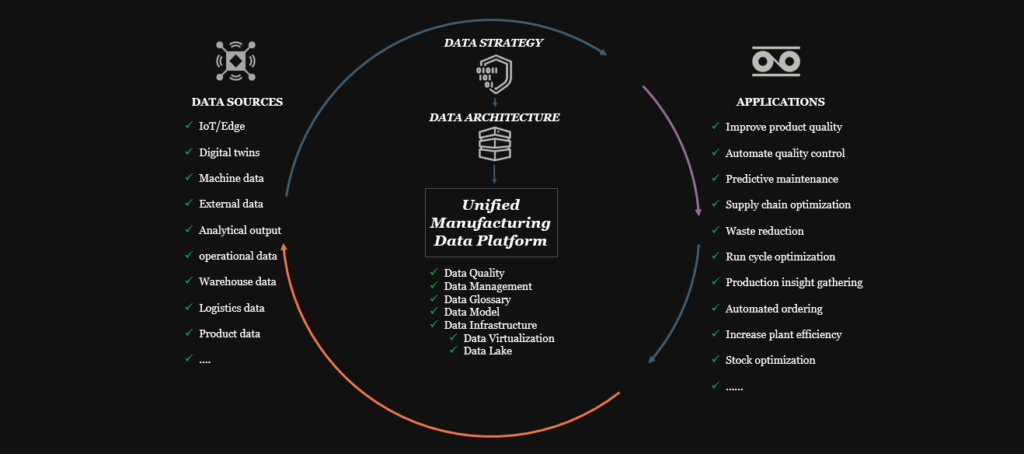

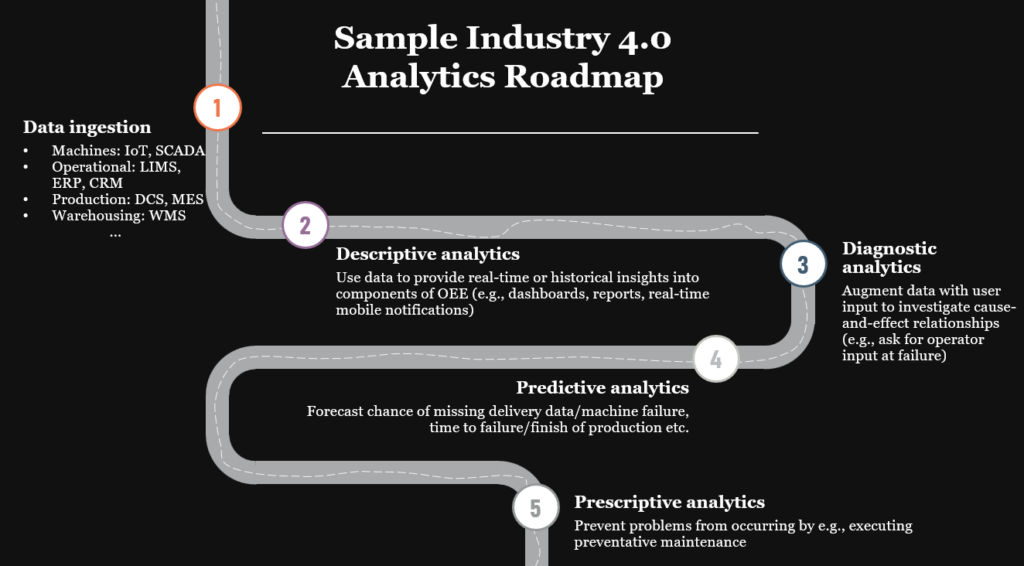

A manufacturing environment is a complex net of OT and IT data. In order to make your manufacturing data driven, first all relevant data has to be integrated and made available. In order to do this, Algorhythm builds performant manufacturing data platforms. Algorhythm can assist your organization in developing a data vision and strategy. Next, this strategy is translated into a data architecture which enables all analytical initiatives. A holistic data strategy unifies all your production data into a central data platform. Algorhythm guides you through the data maze towards a clear and unified data environment. This data platform makes the data available for all thinkable manufacturing data applications such as predictive maintenance, waste & scrap reduction, run cycle optimization, etc….

· Step 2 – Analyze

Once all relevant data (IIoT, Scada, Lims, ERP, CRM, MES, WMS, ….) is made available, our data scientists can leverage all this data towards into valuable insights and actionable recommendations. Machine Learning can be applied to manufacturing data for a myriad of applications such as OEE, failure predictions, production planning, production parameter optimization, demand forecasts,….Our combination of industry and AI knowledge results in a focus on those analytical initiatives which are actionable and bring most value to your manufacturing.

· Step 3 – Act

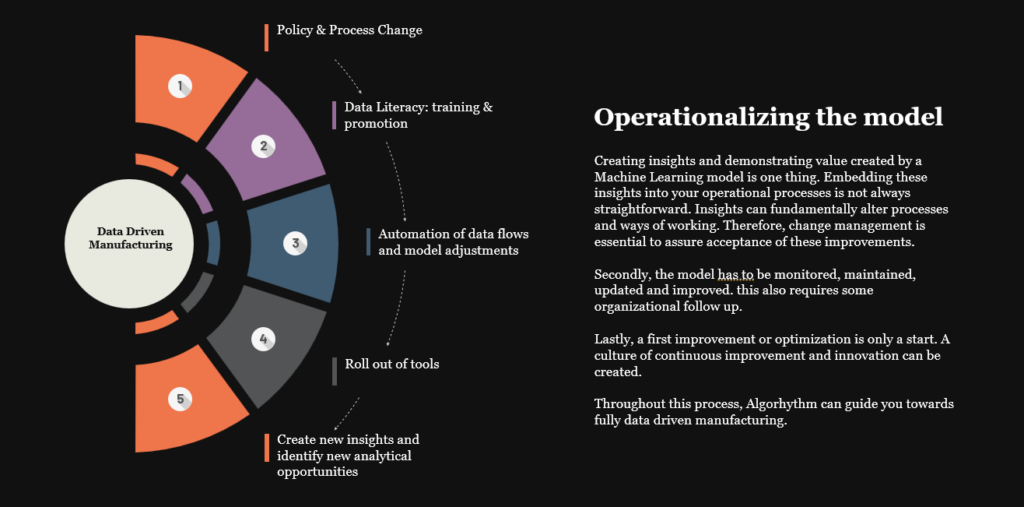

Creating insights and demonstrating value created by a Machine Learning model is one thing. Embedding these insights into your operational manufacturing processes is not always straightforward. Insights can fundamentally alter processes and ways of working. Therefore, change management is essential to assure acceptance of these improvements. Secondly, the ML models, once operational, have to be monitored, maintained, updated and improved. this also requires some organizational follow up. Algorhythm applies MLOps to assure a smooth continuous use of ML models.

Lastly, a first improvement or optimization is only a start. A culture of continuous improvement and innovation can be created.

Throughout this process, Algorhythm can guide you towards fully data driven manufacturing.